Alu-Wood Veneer: The Modern Material Blending Natural Aesthetics and Industrial Intelligence

Standing inside an airport terminal, touching the exquisite wood-grain decoration on the wall, a cold metallic texture lies beneath the delicate grain. This seemingly contradictory aesthetic is quietly shaping the future of architecture and home interiors.

The unique grain and texture of solid wood have long been admired, yet it has inherent limitations in fire resistance, moisture resistance, and deformation prevention.

Aluminum, as a lightweight, corrosion-resistant metal, naturally lacks the warm touch and natural beauty of wood.

The emergence of aluminum-wood composite materials aims to resolve this contradiction—perfectly marrying the stability of aluminum alloy with the aesthetic qualities of wood.

01 Material Fusion

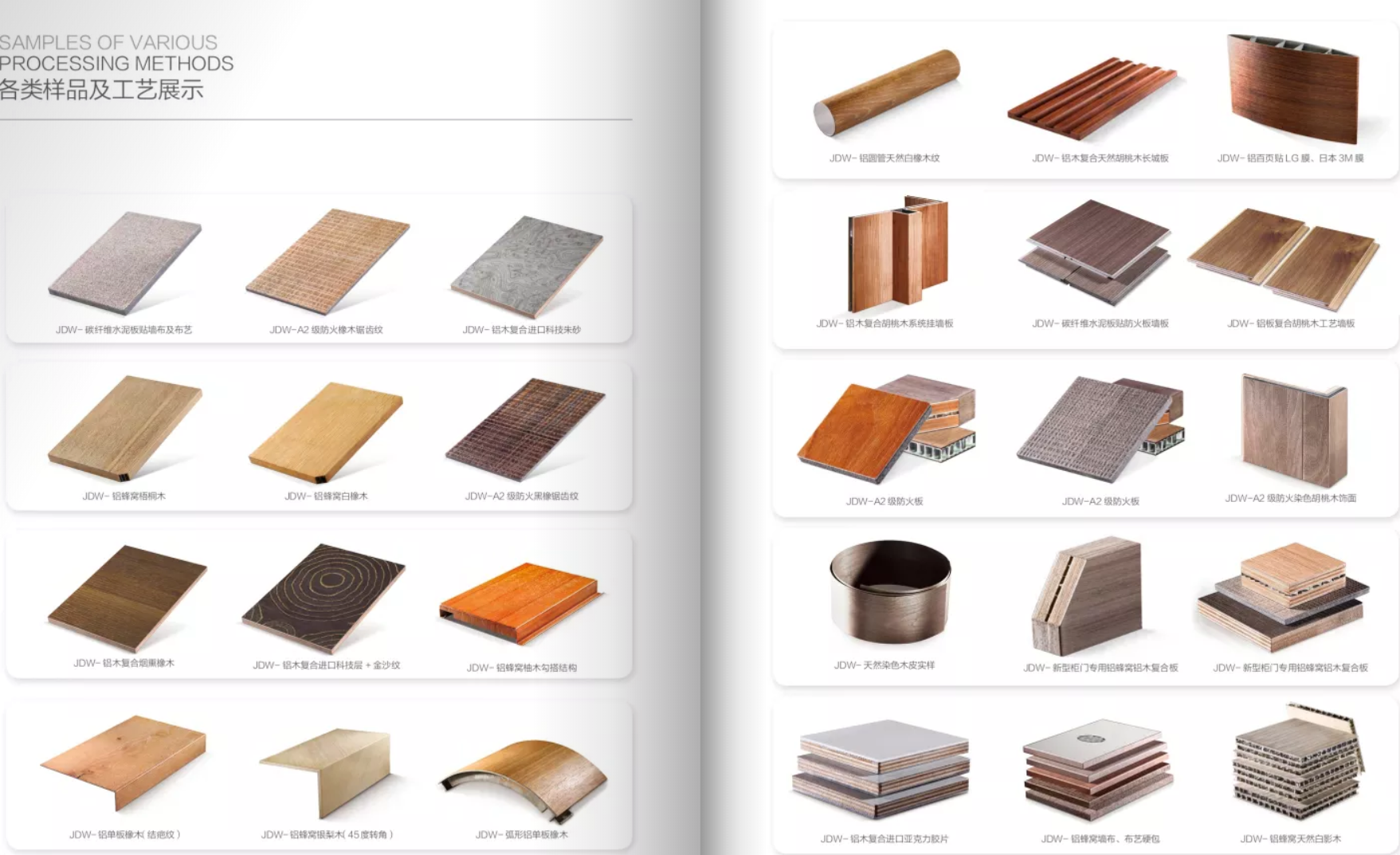

Alu-wood veneer, also known as aluminum-wood composite material, is a type of decorative building material created by bonding metal aluminum with wood-based materials through specific processes. This material ingeniously combines the advantages of both components, achieving a comprehensive performance difficult to attain with a single material.

Structurally, alu-wood veneer typically features a multi-layer composite design. For instance, it may use a wood-based material as the core layer, with aluminum alloy sheets as the surface and backing layers, bonded together using adhesives and hot-pressing techniques.

Other structural forms exist, such as composites consisting of a surface decorative layer, substrate layer, support layer, and backing layer. The support layer might incorporate an aluminum honeycomb structure to enhance the material's overall performance.

The design philosophy of this material is clear: preserve the texture of wood while gaining the properties of metal. Aluminum-wood composite decorative panels can be used in public spaces and hotel interior projects with specific fire safety requirements, and have become an important direction in the research and development of wood-based composites.

02 Core Characteristics

The reason alu-wood veneer materials are favored by the market lies in their combination of the dual advantages of wood and metal, resulting in unique product properties.

In terms of physical performance, this material is lightweight yet strong. Aluminum alloy itself has a density only about one-third that of steel or copper, giving the material excellent lightweight characteristics. Meanwhile, after the aluminum sheets are composited with a wooden core layer, the material's tensile strength can reach 100-280 N/mm².

Environmentally, alu-wood veneer materials perform exceptionally well. Aluminum, being a highly recyclable metal, generally achieves a recycling rate of around 85% for everyday items, and up to 98% for architectural aluminum. This means that after the composite material reaches the end of its service life, the aluminum portion can be almost completely recycled and reused.

The material's technical performance is also comprehensive, including multiple characteristics such as fire resistance, moisture resistance, corrosion resistance, scratch resistance, and thermal insulation. Particularly in terms of fire performance, aluminum-wood composite decorative panels are widely used in public spaces with special fire safety requirements.

03 Manufacturing Process

The manufacturing process of aluminum-wood composite materials is a technological procedure that blends tradition with innovation, primarily involving key steps such as wood core preparation, aluminum sheet surface treatment, and adhesive bonding.

One core technique is aluminum surface treatment technology, commonly including fluorocarbon spraying and powder electrostatic spraying. These treatments not only enhance the weather resistance and decorative quality of the aluminum but also provide a good foundation for subsequent bonding with wood.

Adhesive bonding is a critical technology in the manufacturing of aluminum-wood composites. Research indicates that when epoxy resin adhesive is used to bond aluminum sheets with the core material, the best results are achieved with a mix ratio of 100:100 between the main agent and hardener. The bond tensile strength remains stable during a curing period of 1-7 days.

Aluminum sheet surface treatment also affects bonding effectiveness. Sanding treatment of the aluminum sheet (e.g., using 80-grit sandpaper) can effectively increase the bond tensile strength.

04 Market Applications

Thanks to their excellent performance, alu-wood veneer materials have found broad application scenarios in the architectural decoration field.

In public spaces, this type of material is widely used in airports, subway stations, hospitals, administrative office buildings, commercial buildings, and other venues with high requirements for fire safety and durability.

Alu-wood veneer materials are also entering the home decoration sector. The all-aluminum home furnishing industry, in particular, is actively exploring the use of various facing materials. From initial spraying and wood grain transfer printing to later PVC, PET decorative films, then melamine decorative paper, and emerging "plant-based wood veneers," the finishing processes for all-aluminum home furnishings continue to diversify.

Regarding pricing, according to market data, similar materials like 2mm thick wood-grain aluminum panels have a market price range of approximately 100-220 RMB per square meter. Products using PVDF fluorocarbon paint coatings can achieve durability performance with 10-15 years of color stability.

05 Comparative Advantages

Compared to traditional wood decorative materials, alu-wood veneer offers distinct advantages. Traditional wood veneer panels are prone to mold and have significant deformation in humid environments; they are also susceptible to shrinkage and cracking in regions with large seasonal climate variations.

In contrast, alu-wood veneer materials are moisture and mold-resistant with minimal deformation, enabling them to adapt to a wider range of climatic conditions.

Compared to all-aluminum materials, alu-wood veneer provides a more natural, warm tactile feel and visual effect. While all-aluminum home furnishings have solved processing issues with aluminum—such as using welded monolithic panels to address panel joining problems and PUR adhesives for aluminum honeycomb panel issues—alu-wood veneer materials offer richer and more diverse aesthetic expression, capable of delivering a natural texture closer to that of solid wood.

In terms of decorative effects, the wood grain patterns on the surface of alu-wood veneer can be achieved through three techniques: heat transfer, water slide decal transfer, and water immersion transfer printing. These offer various wood grain patterns like walnut, beech, and oak, and can even support custom textures.

As technology advances, new forms of aluminum-wood composite materials continue to emerge. From aluminum-wood composite decorative panels to aluminum honeycomb core composite boards, and now to "plant-based wood veneers" integrated with AI intelligent lighting and shadow technology.

In modern factories, aluminum honeycomb cores flow steadily on conveyor belts; intelligent spraying systems precisely apply eco-friendly coatings; hot presses firmly bond the multiple material layers together.

This material, which fuses natural aesthetics with industrial intelligence, is providing a brand-new choice for modern spaces that pursue both texture and function.